Dongguan Baoding Precision Instrument Co. Ltd.

Miss.Cai 13717346368

Telephone: 0769-85588096Fax: 0769-82688299

Email: 13717346368@163.com

URL: www.www.chinaenglish.net

Address: No. nine Park Avenue, Houjie Town, Guangdong, Dongguan, China, No. 23

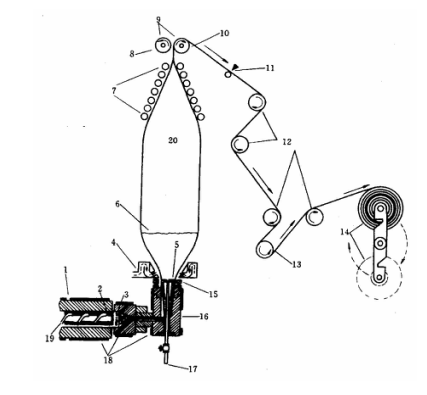

Application, principle and process diagram of small film blowing machine in laboratory

1、 Use

Extrusion film blowing refers to the process of double folding plastic film obtained by continuous extrusion of plastic melt through the die under the action of a certain temperature and shear force, blowing by compressed air, cooling by air ring and frequency conversion traction. This machine is mainly used to detect the film blowing feasibility of polymer materials, the colloidal condition in the materials, and the dispersion of colored dispersions, control mixtures and extrudates.

2、 Principle

The essence of blow molding is blow molding by compressed air in the extruded parison. Blow molding is based on high polymer with high molecular weight and large intermolecular force. A blow molding die is installed at the front end of the extruder. After the viscous plastic is extruded from the die of the screw machine into a pipe blank, it is evenly blown into a larger pipe film by the compressed air introduced into the bottom of the head. In the process of being pulled upward, the expanded pipe film is stretched longitudinally and cooled gradually, and then clamped by the herringbone plate and pulled by the traction roller to form a plastic film with a certain diameter, Finally, it is wound into a double folded film roll.

1. Extrusion barrel; 2. filter screen; 3.perforated plate ;4.air ring ;5. core die;

6. Condensing line ;7. guide roller; 8. rubber pinch roller ;9.pinch roller ;10. stainless steel pinch roller (passive)

11. Processing rod ;12. guide roller ;13.equalizing tensioning roller ;14. winding roller ;15. die ring

16. Die ;17. air inlet; 18. heater ;19. resin ;20. membrane tube

- 2021-11-17

- 2021-11-13

- 2021-11-12

- 2021-11-11

- 2021-11-10

- 2021-10-14

- 2021-10-12

- 2021-10-08

- 2021-09-13

- 2021-09-09Overview of plastic mixer