Location:Home > News information > Solution > 正文

Contact

Dongguan Baoding Precision Instrument Co. Ltd.

Miss.Cai 13717346368

Telephone: 0769-85588096Fax: 0769-82688299

Email: 13717346368@163.com

URL: www.www.chinaenglish.net

Address: No. nine Park Avenue, Houjie Town, Guangdong, Dongguan, China, No. 23

Description of head and mouth film of single screw extrusion film blowing machine

2021-08-24 15:06:48

Hits:2131

Description of head and mouth film of single screw extrusion film blowing machine

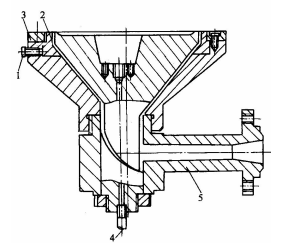

1 mandrel shaft 2 die 3 adjusting screw 4 compressed air inlet 5 neck

1. Cooling air ring

The air ring is a cooling device for film discharge. It is located around the membrane tube above the die (die head), and the rotation can adjust the air output to control the cooling speed of the membrane tube. Generally speaking, clockwise rotation (downward) increases the air output, and the cooling speed becomes faster. Counterclockwise rotation (upward) reduces the air output and slows down the cooling speed. The air volume directly affects the stability of the membrane bubble. The instability of membrane bubbles may be the main cause of wrinkling.

2. Traction device

The expansion degree of the tube film can be controlled by introducing compressed air into the head to blow the tube blank into a film tube and adjusting the amount of compressed air.

The film blowing ratio indicates the change of tube blank diameter. It shows that the polymer is subjected to transverse tensile force in viscous flow state, and the usual film blowing ratio is between 2-6.

Blow molding is a continuous forming process. In actual production, the same annular gap die is often used to control the film thickness by adjusting different traction speeds. Therefore, the longitudinal and transverse mechanical strength of blown film is different, and the longitudinal strength is generally greater than the transverse strength.

The function of the herringbone plate is to stabilize the cooled membrane tube, prevent it from shaking, and clamp the membrane tube flat. The traction pinch roller is composed of a rubber roller and a metal roller. Its function is to pull and stretch the film. The speed can be adjusted. The distance from the traction roller to the die has a certain impact on the performance of the film tube in the forming process, which determines the cooling time before the film tube is folded into double fold. This time is related to the thermal performance of the plastic.

3. Winding device

It is a device for winding blow molded products. It consists of a rubber roller, a metal roller and a winding roller. The standard torque motor can adjust the operation according to the load resistance.

4. Air compressor

The function of the film blowing unit is to provide air blowing and cooling film tubes. Through the adjustable air valve and air ring to change the size of the air supply, a film blowing or cooling film pipe is formed. The larger the air supply, the larger the expansion diameter of the membrane tube, and vice versa. In the actual operation process, the air intake of air valve and air ring should be adjusted repeatedly and carefully until a stable membrane pipe is formed.

5. Electric control cabinet

The electrical control box of the film blowing unit includes the functions of single screw extruder, traction device, winding device, blowing device, start and speed regulation, heating and stop of screw extruder. Startup and speed regulation of traction device. The start-up of the winding device is to speed regulation and other functions.

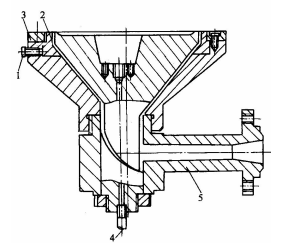

This method is a flat extrusion and blowing method of plastic, which is a device for extruding tubular blank upward, so its head and die are steering right angle type. There is a corresponding relationship between the width and length of the gap of the die and the thickness of the film. Before leaving the factory, the gap of the die has been strictly adjusted, and the user does not need to adjust it. If the gap deviates due to the action of external force, it must be adjusted. The purpose of its adjustment is to make the circumferential wall thickness of the membrane tube consistent.

1 mandrel shaft 2 die 3 adjusting screw 4 compressed air inlet 5 neck

1. Cooling air ring

The air ring is a cooling device for film discharge. It is located around the membrane tube above the die (die head), and the rotation can adjust the air output to control the cooling speed of the membrane tube. Generally speaking, clockwise rotation (downward) increases the air output, and the cooling speed becomes faster. Counterclockwise rotation (upward) reduces the air output and slows down the cooling speed. The air volume directly affects the stability of the membrane bubble. The instability of membrane bubbles may be the main cause of wrinkling.

2. Traction device

The expansion degree of the tube film can be controlled by introducing compressed air into the head to blow the tube blank into a film tube and adjusting the amount of compressed air.

The film blowing ratio indicates the change of tube blank diameter. It shows that the polymer is subjected to transverse tensile force in viscous flow state, and the usual film blowing ratio is between 2-6.

Blow molding is a continuous forming process. In actual production, the same annular gap die is often used to control the film thickness by adjusting different traction speeds. Therefore, the longitudinal and transverse mechanical strength of blown film is different, and the longitudinal strength is generally greater than the transverse strength.

The function of the herringbone plate is to stabilize the cooled membrane tube, prevent it from shaking, and clamp the membrane tube flat. The traction pinch roller is composed of a rubber roller and a metal roller. Its function is to pull and stretch the film. The speed can be adjusted. The distance from the traction roller to the die has a certain impact on the performance of the film tube in the forming process, which determines the cooling time before the film tube is folded into double fold. This time is related to the thermal performance of the plastic.

3. Winding device

It is a device for winding blow molded products. It consists of a rubber roller, a metal roller and a winding roller. The standard torque motor can adjust the operation according to the load resistance.

4. Air compressor

The function of the film blowing unit is to provide air blowing and cooling film tubes. Through the adjustable air valve and air ring to change the size of the air supply, a film blowing or cooling film pipe is formed. The larger the air supply, the larger the expansion diameter of the membrane tube, and vice versa. In the actual operation process, the air intake of air valve and air ring should be adjusted repeatedly and carefully until a stable membrane pipe is formed.

5. Electric control cabinet

The electrical control box of the film blowing unit includes the functions of single screw extruder, traction device, winding device, blowing device, start and speed regulation, heating and stop of screw extruder. Startup and speed regulation of traction device. The start-up of the winding device is to speed regulation and other functions.

Related

- 2021-12-06

- 2021-11-18

- 2021-11-15

- 2021-11-09

- 2021-11-05

- 2021-10-22

- 2021-10-21

- 2021-10-15

- 2021-10-11

- 2021-09-16Production process of plastic extruder